Description

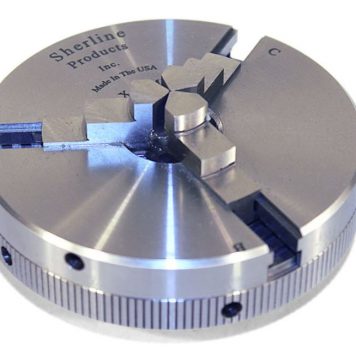

Sherline 4 Jaw Chuck 3.1 Inches ER-16 1078

4 Jaw Chuck 3.1 Inches ER-16

Sherline offers their 3.1″ three-jaw and four-jaw self-centering chucks with a 22 x 1.5 mm threaded hole. It is for use on Sherline’s optional ER-16 spindle nose. They can also be used with certain other ER-16 spindles that use the 22 x 1.5mm thread for the collet nut.

Self-centering chucks offer a quick and convenient way to hold a workpiece while it is turned on the lathe. A chuck can also be clamped to a mill table to hold a part for milling. Sherline manufactures our own chucks to a high degree of precision on CNC machines. The jaws are ground and fitted to each chuck by skilled technicians to assure maximum accuracy. Runout is specified to be .003″ or less at the chuck jaws.

Three-jaw chucks are normally used to quickly hold round or hexagonal stock. The jaws scroll together as the ring of the chuck is turned. Parts can be held quickly with relatively good accuracy. A self-centering 4-jaw chuck is adjusted like a 3-jaw chuck and can be used on round or square stock, although the stock must be accurate for all four jaws to grip properly. They can be used to quickly hold square material or to provide an extra jaw to spread out the crushing force when holding thin tubing.

NOTE

The chuck should not be used in applications where spindle speed exceeds 3000 RPM. If purchasing any of these chucks for use on a non-Sherline ER-16 spindle, confirm that the spindle nose thread is 22 x 1.5 mm before purchasing. The Sherline chuck has a collar that is machined flat at the back to seat against the face of the Sherline ER-16 spindle. This may not be compatible with some non-Sherline ER-16 collet adapters or industrial tool holders. Runout accuracy cannot be guaranteed unless used with a Sherline spindle.

Jaw Options

- If speed and ease of use are more important than maximum accuracy, we can send you a chuck that is loose right from the start (No extra charge). Please email us and indicate “loose jaws”.