Description

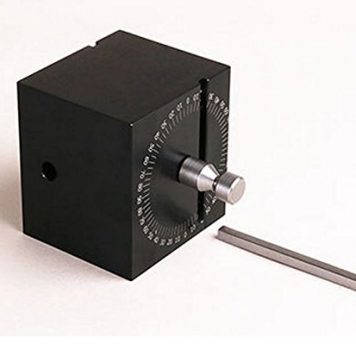

Sherline Mill Extended Headstock Spacer Block 1299

Having the option to extend the headstock further out can sometimes allow surfaces to be machined that could not otherwise be reached without breaking down the setup and re-clamping the part. The spacer moves the spindle out an additional 2-1/2″. This is twice as far as the standard P/N 1299 spacer block. Making it in one piece rather than stacking up two 1297 spacer blocks increases the mill’s rigidity and accuracy. In many cases, it is much easier to increase your machinable surface area by using this spacer than to re-clamp the part. Precisely machined keyways keep the headstock accurately aligned. A precision ground alignment key is included.

NOTE: This part is not recommended for use on the Sherline lathe.

Riser Block

- Riser Block Body Material Aluminum

- Body Coating Black Anodized

- Body Dimensions (H x W X D) 2.5″ x 2.5″ x 3″

- Pivot Pin Case Hardened 12L14 Steel

- Alignment Key Material Precision Ground Steel

Installing the Spacer Block

Like the P/N 1297 standard headstock spacer block, the P/N 1299 extended spacer block is installed over the mill column saddle pin. A precision ground alignment key is installed between the spacer block and the saddle. A second alignment key is installed between the spacer block and the headstock. If the headstock is to be aligned in any position other than straight up and down, the second alignment key is not installed so the headstock can be rotated on the pin. When in the desired position, the cone point set screw in the side of the block is tightened using a 5/32″ hex key.

The point of the set screw engages a tapered groove in the pin, pulling the headstock down onto the alignment key as the screw is tightened. Note that the pins are slightly loose in both the saddle and the spacer block. This is the way they are designed, as the proper function of the pin is simply to pull the headstock down onto the alignment key and to let the keyway do the aligning rather than the pin.